Ceramic Bearing System - CeraDyna

Zirconia offers a variety of durable and cost-effective success stories that can replace traditional materials

- High hardness

- Wear resistance

- Low thermal expansion coefficient

- Low conductivity

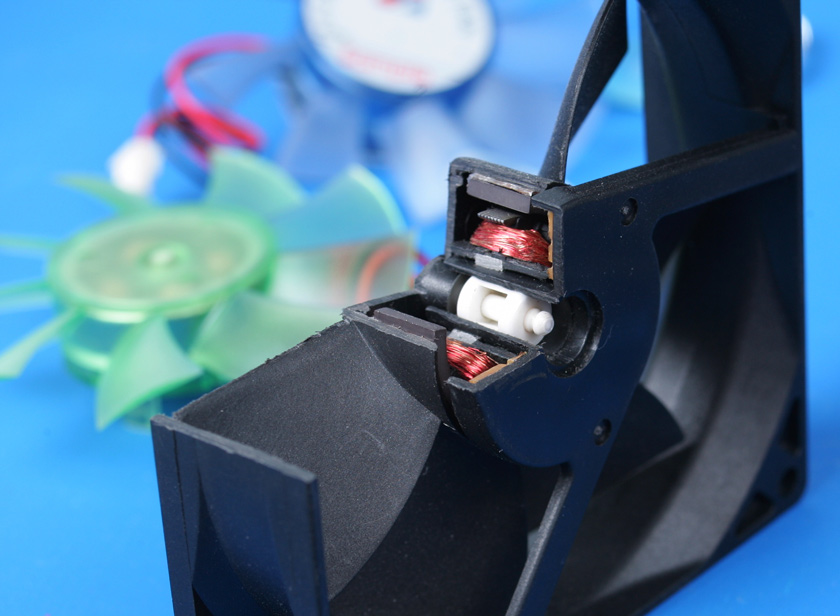

The ceramic shaft is very precisely machined, with a very fine surface texture, well in advance of the traditional steel shaft. ARX launched its A series of Ceradyna brand fans late in 2001, and this year the company plans to launch its Ceradyna C series, which feature a combination of ceramic shaft and ceramic bearing. This combination offers very durable and smooth operation, at the same or slightly less cost than a two-bearing system, while making less noise.For ARX, the ceramic design approach has been a success, with a very positive market response, and the company has managed to increase market share.

「More and more people are looking into ceramic technology. Ceramic materials offer many advantages. They are very durable and resistant to heat and humidity.」~ Excerpt from EuroTrade

Product Design → Molding Design & Simulation → Molding Developing

Powder → Mixing

Grinding → Honing → Chamfering → Lapping → Facing

Contact Surface Pattern、Noise Level、Manufacture precision、Hardness、Feasibility、Rotation precision、Life Hour